- 3 October 2020

- Not categorized

- Posted by SAITO

- Comments Off on Bargains

In questa sezione troverete giacenze di magazzino offerte ad un prezzo eccezionale: turbocompressori nuovi originali, complementi d’applicazione, motori, parti motore e tanto altro ancora!

- 1 May 2020

- Not categorized

- Posted by SAITO

- Comments Off on Thermal Blankets and Bandages

- 1 May 2020

- Not categorized

- Posted by SAITO

- Comments Off on Downpipes

- 1 May 2020

- Not categorized

- Posted by SAITO

- Comments Off on Flanges and Adapters

Exhaust Risers

Made of stainless steel to resist salt corrosion- 1 February 2019

- Not categorized

- Posted by SAITO

- Comments Off on Exhaust Risers

Particularly when the inboard marine engine is close to the waterline, it is often necessary to include the so-called “exhaust riser”, a component connected directly to the exhaust manifold. Normally the riser has an external over-wrap where the water that surrounds the exhaust gas pipe circulates, guaranteeing the cooling of the entire circumference of the pipe itself. The exhaust riser of a marine engine aims to guartantee the collection, the mixing and the engine cooling water and fuel gas expulsion.

Exhaust manifolds and risers are therefore essential components for the correct operation of the direct or indirect cooling system of the inboard marine engine.

For all the most common inboard marine engines – Volvo Penta, Yanmar, Iveco Aifo, Mercury Mercuiser just to name a few – SAITO, through its commercial partner SAILOG, sells exhaust manifolds and risers, pipe elbows, bends, dual chamber exhausts and heating exchangers all of them made of stainless steel for deep

Marine Turbochargers

Made with noble materials to cope with marine corrosion- 1 January 2019

- Not categorized

- Posted by SAITO

- Comments Off on Marine Turbochargers

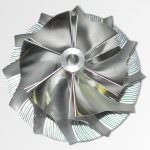

Forged Compressor Wheels

Improved performance and reliability compared to normal impellers- 4 April 2016

- Not categorized

- Posted by SAITO

- Comments Off on Forged Compressor Wheels

The need to get more power and torque from the engine makes it necessary to use turbochargers capable of working at higher compression ratios (up to 5:1), higher rotational speeds and high derived temperatures due to the effect of increased air compression. When the turbocharger is used in heavy duty applications – such as city buses, trucks for local deliveries, earth moving machines, sports cars and so on – it’s speed has great variations this strongly stresses the Turbocharger’s internal components, including the Compressor Wheel.

Due to the increased performance of both engines and turbochargers, Standard die-casted compressor wheels has reached the limit of their resistance and so – in order to increase Turbocharger reliability – a new production method has been developed, namely for mechanical processing, from the a special Aluminum bar. The standard molded Compressor Wheel shows failure problems due to stress and often due to fusion defects, to oxides or other impurities

Garrett Classic Turbo

Supercharging from the past updated with modern technology- 1 February 2016

- Not categorized

- Posted by SAITO

- Comments Off on Garrett Classic Turbo

The Turbo Garrett Classic line sets itself an ambitious goal: to make historic cars also benefit from technological progress. Sacred monsters of motoring, cars that due to their "venerable" age often need spare parts that are now out of production... and the turbo is no exception! If the original component is not overhaulable or available or there is no need to comply with the requirements of a certification - see ASI Targa Oro - it is possible to replace the entire turbocharger with a compatible product, aesthetically similar and at the same time updating technology. The distribution of the Garrett Classic Turbos will start right from Europe, the old continent which, starting from the 70s and 80s, was the forerunner of the turbo revolution in the automobile.

The range will be constantly updated, technical and commercial information can be requested from SAITO by contacting +39 071715693 / info@saito.itPGEgbmFtZT0iYWxmYSI+PC9hPg==JTNDYSUyMG5hbWUlM0QlMjJmaWF0JTIyJTNFJTNDJTJGYSUzRSUzQ2gyJTNFQUxGQSUyMFJPTUVPJTNDJTJGaDIlM0UlMEElM0NhJTIwaHJlZiUzRCUyMmh0dHBzJTNBJTJGJTJGd3d3LnNhaXRvLml0JTJGd3AtY29udGVudCUyRnVwbG9hZHMlMkYyMDIzJTJGMDMlMkZnYXJyZXR0LW [...]

Vintage Turbocharger (Classic Car)

Analysis of the causes of breakage and estimates for the repair of turbochargers of vintage cars- 1 February 2016

- Not categorized

- Posted by SAITO

- Comments Off on Vintage Turbocharger (Classic Car)

The turbochargers for vintage cars are only apparently the same as the current ones but in the reality it is not so. They are more “sensitive” and overall less reliable because the materials used in the past were less efficient. As well as the production and the assembly technologies were less refined. The turbochargers were also used on less “intelligent” engines, there was less control of the combustion parameters which made them less stable the exhaust gas conditions.

All this to say, before defining whether a turbo can be remanufactured, it is good to view it and decide how to proceed and whether it is really worth it. Remanufacturing a vintage turbo can cost approximately from € 250 to € 600 with more or less optimal results depending on the level of action taken. Sometimes a cracked turbine housing can be restored but the work will be more expensive and the result not totally reliable.

- 1 April 2014

- Not categorized

- Posted by SAITO

- Comments Off on Turbo Gasket Kits